vYulvi Zaika1*, Nuril Charisma1, and Luh Leta Milleila Nursanti1 1Departement of Civil Engineering, Universitas Brawijaya, 65145 Malang East Java, Indonesia (Lightweight-GB)

This page serves as a reference summary of the original research article. : Lightweight-GB fill to prevent soft ground deposit failure

Abstract. As a foundation for transportation infrastructure, soft ground has limited bearing capacity and high compression. To prevent embankment failure, lightweight material is suggested. In the construction of road embankments, EPS can be regarded as an environmentally sustainable lightweight fill material. The study’s goal is to create a formula for GB (Geo-bead) concrete mixing as a lightweight fill ingredient. Several tests are performed on the material specimens, including bulk density, interface shear strength, unconfined compression, and a SEM of the composite material. The tests were designed to determine the physical and mechanical qualities using GB percentages (20%, 30%, and 40%). Composite material has a lower density than compacted sand. The friction angle falls between the adhesion of GB-GB and GB-cemented sand. A ductile failure pattern develops because the bond between cement paste and GB is less than that between cement sand. The composite material’s CBR passed embankment specifications. In the case of an embankment on soft soil, the 2D FEM analysis expressed settlement by compacted sand and lightweight fill material. Lightweight geo bead backfill decreases soft soil settlement, preventing failure.(Lightweight-GB)

or in place of heavy fill materials to prevent unacceptable loading on underlying soils and adjacent structures. Research on the type of light embankment on soft soil has developed intensively based on the need for a light embankment. Expanded Polystyrene (EPS) blocks have been known for a long time as one of the materials for lightweight structures to reduce the settlement and the duration time for subsidence due to consolidation on soft soil. In addition, the use of EPS will reduce lateral loads. However, the EPS block disadvantages are long-term compressibility (creep) and block destruction by plastic deformation [4]. Recently EPS beads or Geo-beads (GB) have been mixed with sand and cement to produce light fill [5, 6]. GB dosage significantly affects the compressive strength of GB lightweight aggregate concrete more than the water and cement ratio. In contrast, cement and sand ratio content is comparatively less important. In 2012, Xu [7] proposed the relationship between density and compressive strength and the relation of density to 4 factors such as cement, ratio water and cement, EPS, and sand. The stress-strain behavior of EPS concrete was similar to regular concrete, with the elastic portion of the stress-strain curve increasing. The other researcher proposed that concrete EPS is appropriate for specific seismic requirements and cyclic load [8]. The proposed lightweight fill material using cement-treated Yangzi River sand and expanded polystyrene (EPS) beads has several advantages for embankment construction. The settlement of the lightweight soil embankment is considerably less than lime-stabilized soil embankment, which is suitable for soft soil embankment.

۲

۱. Introduction (Lightweight-GB)

Many cases of structural collapse have occurred due to foundations on soft soils. Those are due to a lack of knowledge about the soil or a lack of data characterizing the soil. The structure will crack along the base of the building; then, the crack will spread to the top of the building. It is hazardous for the building occupant. In the case of rigid pavement structures, the gap between the blocks will become more significant. The collapse of embankments built on soft soils is due to the low bearing capacity of the soil and the continuous consolidation settlement. Soft soils generally consist of clays with Hollosen age (< 10000 years), scientifically formed from deposition in coastal alluvial lands, rivers, lakes, and swamps. The distribution of soft soil in Indonesia is generally found in coastal plain areas, among others: East Sumatra, North Java, West – South Kalimantan Island, and South Papua Island [1]. In the case of embankments on soft soils, improvements to the natural soil should prevent collapse, such as using vertical drains to accelerate the consolidation process, using additives to modify the physical and mechanical properties of the soil, or reducing the embankment load by using lighter materials. Expanded polystyrene is a highly effective solution for many civil engineering problems, especially pavement structures [2, 3]. There are advantages of construction with EPS geofoam, such as having high compressive resistance, saving time because easy to handle without the need for special equipment, replacing compressible soils,

۱

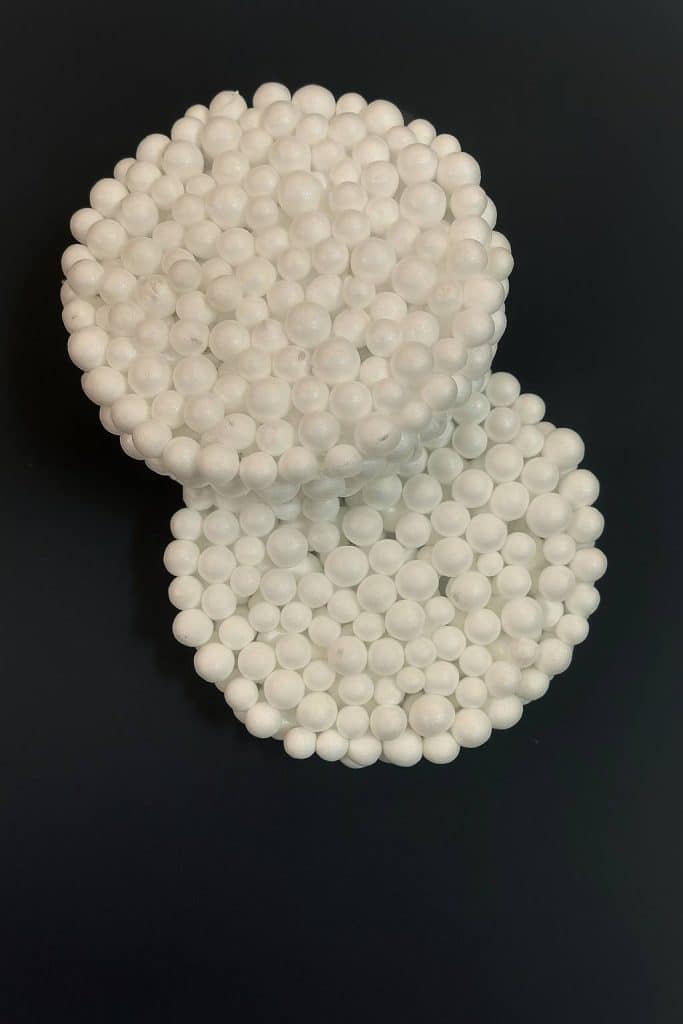

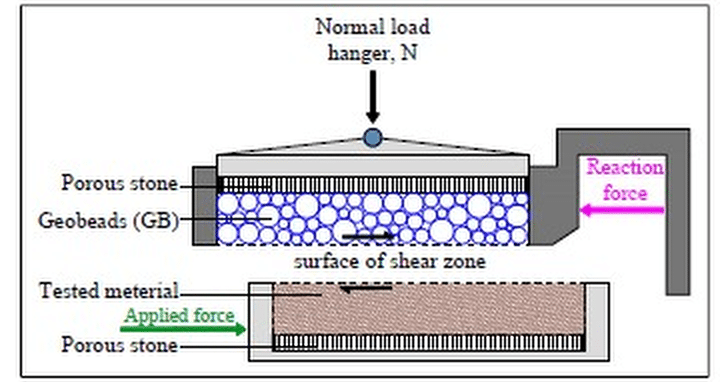

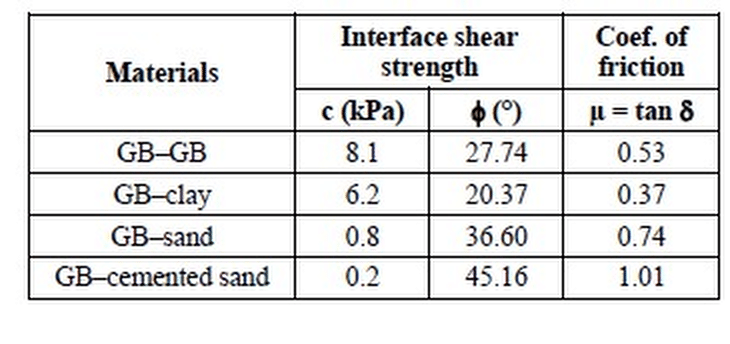

The interface shear strengths of soil-geosynthetic and geosynthetic-geosynthetic are determined by direct shear (ASTM D 5321). This test method covers a procedure for determining the shear resistance of GB-clay, GB-GB,GB-sand, and GB-cemented sand(Lightweight-GB). The samples aredivided into two parts that contact a horizontal surface.The glued GB granules fill (Figure 1) the direct shear ring (diameter = 6.2 cm, thick = 1 cm). The GB is placed on top of GB, clay soil, sand soil, and cement-treated sand (Figure 2)

۲.۲ Materials

The details of the soil characteristics are summarized in Table 1.

](http://www.azmabeton.com/wp-content/uploads/2025/09/a-300x117.jpg)

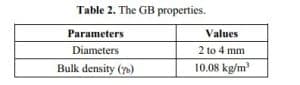

The cement produced by Indonesia Gresik Portland Cement was ASTM Type I. The cement dosage is determined at 8% dry-weight sand based on the Portland Cement Association [10] and Unified Facilities Criteria [۱۱]. The GB is a manufactured product made from Expanded Polystyrene (EPS) with properties shown in Table 2.

Based on previous research [12], the density of the lightweight fill can be effectively controlled by the amount of GB(Lightweight-GB) in the composite material. The fraction of GB is a volume ratio with sand of 0%, 20%, 30%, and ۴۰%.

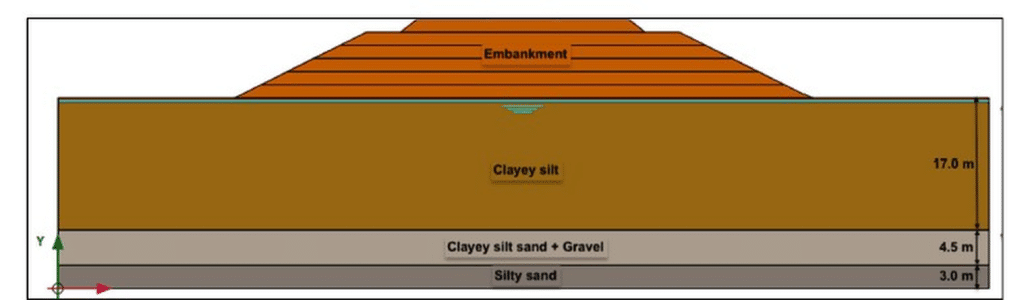

۲.۳ Finite element analysis

The case study for 2D finite element method (FEM) analysis is the construction of the Gempol–Pasuruan Highway, which takes place at STA +31.000 in the Kedawung Wetan, Pasuruan Regency, East Java Province, Indonesia. The FEM model was created to adjust the state of the embankment construction above the soft soil layer as shown in Figure 3a. Secondary data from field conditions are collected as soil parameters and laboratory tests based on previous studies [13]. The lightweight fill material with GB (Lightweight-GB) was input as the composite soil using the properties from laboratory test results. The embankment model was 10.2 m in height, and the groundwater level was 0.5 meters below the surface. The traffic load is applied to the embankment model to examine the behavior of the soil, particularly the soft soil layer. Three nodal points on the surface, in the middle, and below the soft soil layer were observed to analyze the behavior of the soft soil, especially the settlements and the excess pore pressure. The parameters of the soft soil layer and compacted sand refer to the previous study as shown in Figure 3(b) [14].

۴

The study aims to formulate EPS concrete mixing as a lightweight fill material. Various experiments explored composite materials in macro and microstructure. The analysis 2D FEM is applied to perform lightweight fill material as embankment with the material parameter, which was determined by the prior experimental tests.

۲. Experimental study

۲.۱ Experimental procedure

The fundamental tests, such as the grain size test (ASTM D6913), the specific gravity test (ASTM D854), and the direct shear test (ASTM D3080), were conducted to examine the soil properties. The unconfined compression test (ASTM D2166) investigates the stress-strain relationship of composite materials.

۳

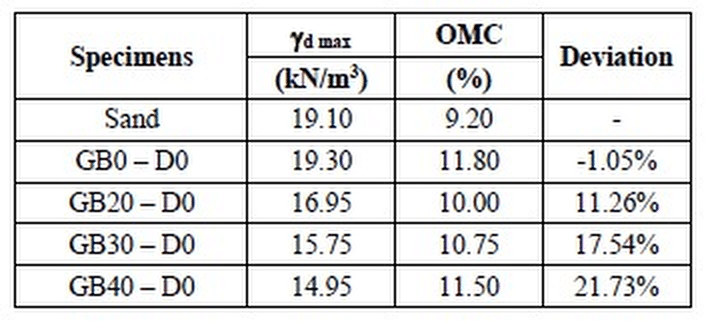

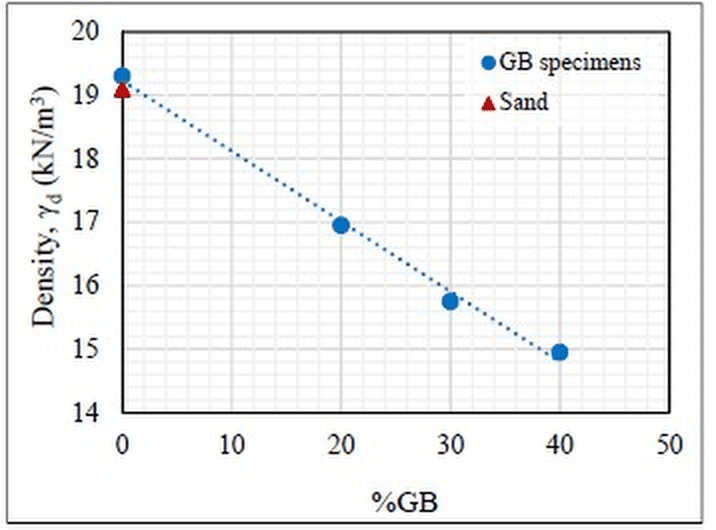

The densities of the compacted sand and the cemented sand indicate an almost similar level. The addition of 8% cement was due to an insignificant change in density. The composite material with GB reduces density significantly. In the case of GB 40% at volume ratio sand, dry density decreases by 21.7%, as shown in Table 4. The density of compacted sand is 19.10 kN/m3, and Equation (1) performs 14.8 kN/m3 for 40% GB.

γd= -0.111x+19.229

Where:

ϒd : dry density (kN/m3)

x : GB dosage (%)

۳.۴ Shear strength of GB composite light fill

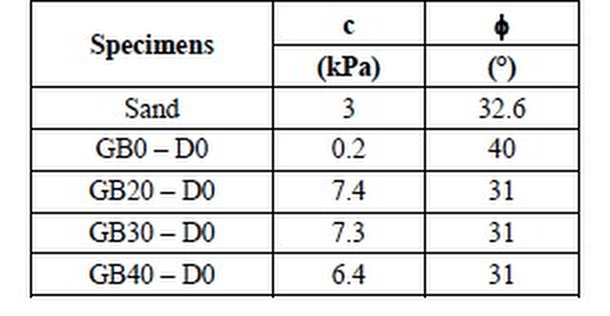

The direct shear test creates the shear strength parameters of composite GB materials. Each composite GB material composition was tested at 0 days, which resulted in the same internal shear angle and a relatively slight change in cohesion, as shown in Table 5.

The shear strength and stiffness of the GB lightweight fill can be controlled by adjusting the amount of cement. The decrease in density does not significantly affect the friction angle or cohesion because the cement percentage remained constant.

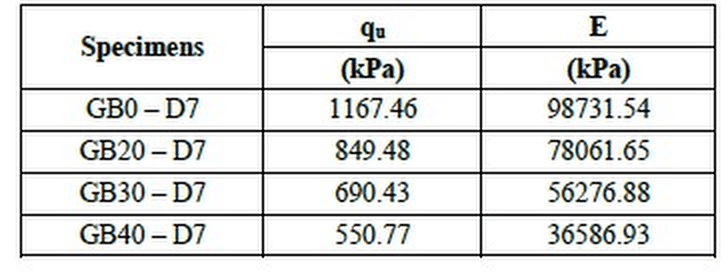

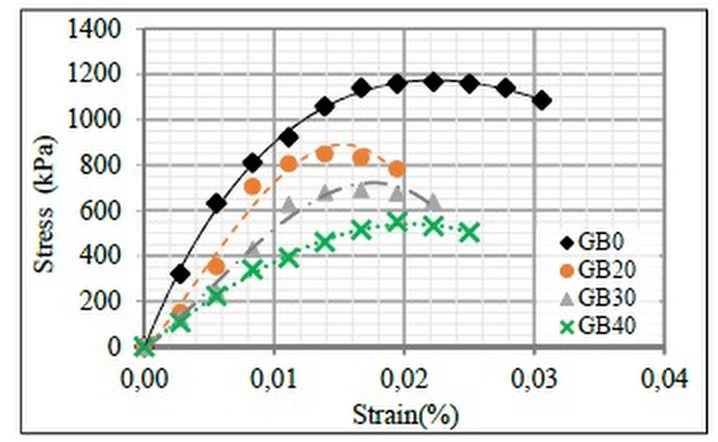

۳.۵ Compressive strength and failure mode of composite material

The unconfined compressive test was performed on GB composite after 7 days of curing. The stress-strain relationship is caused by the compressive load. As a consequence of the testing, the modulus of elasticity (E) of the GB composite fill material is obtained. Table 6 and Figure 8 show the results of the unconfined compression test. The modulus of elasticity decreases as the GB % in the specimens increases. Material stiffness can be assessed at the stress-strain curve level, where the steeper the curve, the stiffer the material. The GB composite material becomes ductile as the fraction of GB increases when the stress-strain relationship of each specimen is examined.

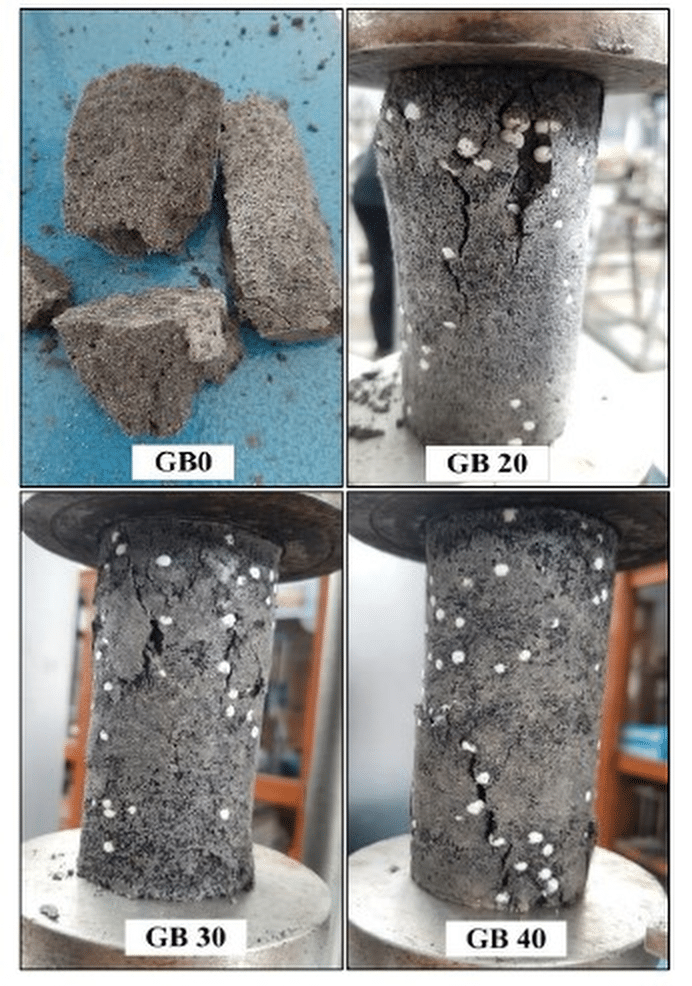

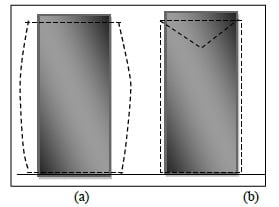

The increasing ratio factor of cement and sand (C/S) makes the material more brittle with constant GB [12]. In addition, the effect of the ratio of water and cement (W/C) is directly proportional to density and strength. In this study, the C/S was set at 8%, while the water would be determined from compaction to produce optimum conditions. Only the change in GB percentage will determine the density and strength. The mixture without GB shows a stress and strain relationship with brittle conditions. The presence of GB changes the material properties to be ductile. The analysis of failure mode is represented by Lewis [16]. Figure 9 shows the failure in the composite material with several GB percentages based on the unconfined compressive strength test. The failure of the material without GB (GB0) occurs when it reaches the maximum stress at which the sample immediately collapses, which exhibits a ductile phenomenon (small elastic deformation without plastic deformation). Brittle failure is the sudden breakage and rapid crack propagation. The deformation moved to the center, while the bottom had a slight deformation compared to the other parts. An overloaded part breaks with no visible distortion and small plastic deformation. The direction of the fracture path is indicated by chevron marks that point toward the origin of the failure as shown in Figure 10 (b). After a brittle failure, it is impossible to ‘fit’ the broken pieces back together again. The GB composite samples represent different phenomena in which, after reaching the maximum stress, the strain increases before failure occurs. With the high percentage of GB, the maximum stress will be obtained with increasing deformation. It shows the ductile phenomenon, Figure 10 (a). In the GB20 sample, the failure pattern changes from brittle to ductile.

۶

![Lightweight-GB fill to prevent soft ground deposit failure (September 2025) 11 Ground level and parameter [14]](http://www.azmabeton.com/wp-content/uploads/2025/09/4-photoaidcom-2x-ai-zoom-1024x389.png)

۳ Results and discussion

۳.۱ Permeability of GB (Lightweight-GB) composite material

GB composite mixtures treated with 20%, 30%, and 40% GB over 28 days of cure were indicated impermeable. The coefficient of permeability (k) of the material was measured at 2.66×10-۵, ۱.۱۰×۱۰-۵, and 7.98×10-۶ cm/s for GB contents respectively. Low to very low permeability rates are considered category level. As silts, silty sands,fine sands, glacial tillts, and layered clays, the materials have poor drainage [15].

۳.۲ Shear strength of the interface

Table 3 shows the adhesion and interface friction angle between GB and some materials.

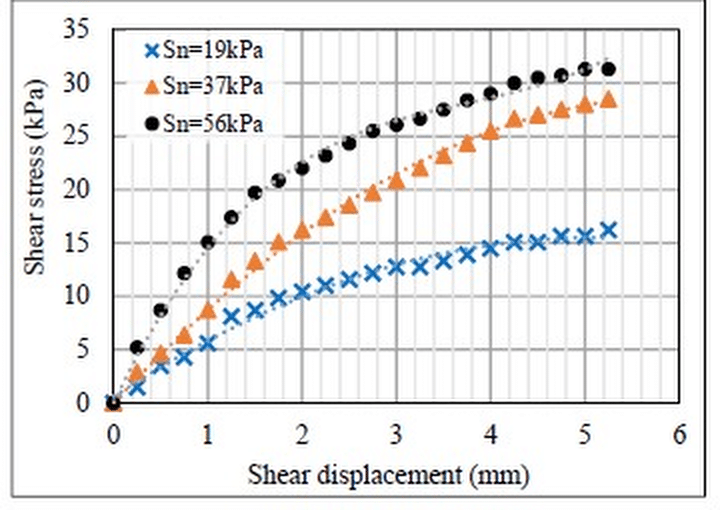

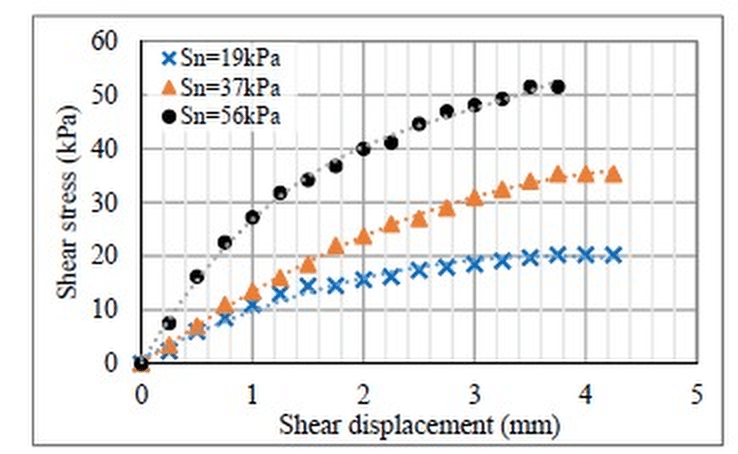

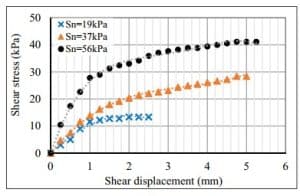

The shear displacement and shear stress for interface GB – GB and GB – cemented soil in sequence are presented in Figure 4 and Figure 5 The interface tests were conducted at three normal stresses 19 kPa, 37 kPa, and 56 kPa. The rate of shear stress development increased with increasing shear displacement until reaching the maximum/peak interface shear strength. After reaching the peak strength, shear strength reduction was observed gradually with further shear displacement to achieve the large displacement. The peak stress of the GB cemented sand interface is higher than GB – sand (Figure 6) and GB – GB. The value of the peak shear stress is estimated to be strongly influenced by the hardness of the material.

interface

The shear strength parameters of the clay are undrained cohesion of 9.18 kPa and friction angle of 0.6۰ [۱۳]. GB material in clay increases the friction angle to ۲۰۰, but the cohesion change is insignificant. The interface strength of GB-cemented sand is greater than that of GBsand. The light and strong behavior of the composite material will be the backfill material.

3.۳ The density of GB (Lightweight-GB) composite light material

Light embankments should have a density smaller than the compacted soil. The density of the compacted soil, in which the sand fraction is dominant in the range of 19 – ۱۸ kN/m3. The embankment material is light-filled when the density is smaller, as shown in Figure 7.

۵

t = TᵥH² / cᵥ

Where:

Tv : nondimensional time factor

H : length of the maximum drainage path

Cv : coefficient of consolidation.

In such cases, the length of time to reach a 90% degree of consolidation is determined by the parameter Cv. The value of Cv is obtained from the root time or log time method from laboratory consolidation experiment data. The coefficient of consolidation is a function of hydraulic conductivity, coefficient of volume change, and water density, as per the following formula:

Cv=k / mvγw

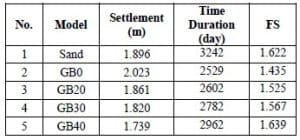

Some laboratory results show that there is a distinct trend for Cv with increasing effective stress v. The Cv does not indicate a constant value. R.G. Robinson and M.M. Allam [20] examined the relationship between stress and the coefficient of consolidation and found that there is clay minerals kaoline and illite suggested an increase but the mineral montmorillonite suggested a tendency to decrease with increasing stress. The results of the study proposed the increase in Cv is due to the mechanical properties of the mineral and the decrease in Cv is due to physicochemical properties. The increase or decrease in the value of Cv is largely determined by the mechanical and physicochemical properties governing the compressibility of soil. The effective stress due to embankment self-weight and the effective overburden stress in the case will decrease with the increase of GB portion. Thus, the increase in effective stresses has the effect of reducing the Cv and consequently duration of time increase. The stability of the embankment is another issue that could lead to collapse. To avoid slope collapse in the preceding case, a slope ratio of 1:2 was chosen. If the slope is steep at a ratio of 1:1, the factor of safety for a sand embankment falls to 1.327, while the FS for 40% GB composite material falls to 1.567. As the GB content goes down, it will impact the safety number. In contrast to the composite material, the change in the safety number for sand fill is fairly large. This mixture will be suitable when the soft soil layer and embankment height are reasonably balanced—using geo-bead, a waste material [21], is an added value besides avoiding the use of reinforcement on high slopes.

۴ Conclusion

The percentage of GB decrease the density of the mixture, but the shear strength parameter has little effect if the cement and sand ratio remains constant. The friction angle is significantly affected by the adhesion between GB-GB and GB-cemented sand. According to SEM data, the GB reduced cement paste and aggregate bonding. The stress-strain relationship represents the ductile failure pattern induced by compression loads. Lightweight fill is formed with the addition of geo-beads and reduces settlement in soft soil layers from 1.896 m to 1.739 m in the case. A particular strength will limit the amount of geo-bead, and the thickness of the soft soil is a consideration in using this mix for the embankment. The time taken to reach a 90% degree of consolidation increases with the increase of the GB portion, but it is shorter than that of compacted sand fill. In this study, the enhancement of stress increases the value of Cv which influences the duration of consolidation. The embankment stability of the GB composite material will perform stability to the steep slope embankment compared to compacted sand. Using GB composite materials will reduce the potential for large settlement and embankment slope collapse. In addition, there is also a spirit to use waste materials.

References

۱. The Ministry of Energy and Mineral Resources of Indonesia, The Geology Division, (Indonesian), Atlas Allocation of Indonesia Soft Soil, 1st ed, (2019) 2. A. Marradi, U. Pinori, G. Betti, Procedia – Social and Behavioral Sciences 53, 1000–۱۰۰۹ (۲۰۱۲) ۳. F. Giuliani, F. Autelitano, E. Garilli, A. Montepara, Transportation Research Procedia 45, 410–۴۱۷ (۲۰۲۰) ۴. T.H. Kim, G.C. Kang, L.K. Park, Environmental Earth Sciences 72, 4, 1109–۱۱۱۶ (۲۰۱۴) ۵. F. Wang, L. Miao, Bulletin of Engineering Geology and the Environment 68, 4, 517–۵۲۴ (۲۰۰۹) ۶. G.E. Abdelrahman, in Proceedings of the Institution of Civil Engineers Ground Improvement 163, 2, 95–۱۰۰ (۲۰۱۰)۷. Y. Xu, L. Jiang, J. Xu, Y. Li, 27, 1. 32–۳۸ (۲۰۱۲). ۸. W. Shi, L. Miao, J. Luo, J. Wang, Y. Chen, Durability of Modified Expanded Polystyrene Concrete after Dynamic Cyclic Loading, Shock and Vibration 2016 (2016) 9. N. Charisma, Y. Zaika, A. Munawir, J of Southwest Jiaotong University 56, 4, 793–۸۰۳ (۲۰۲۱) ۱۰. Portland Cement Association, Soil-Cement Laboratory Handbook (PCA, 1992) 11. Unified Facilities Criteria, Soil Stabilization for Pavements (UFC, 2020) 12. H.L. Liu, A. Deng, J. Chu, Geotextiles and Geomembranes 24, 6, 331–۳۳۸ (۲۰۰۶) ۱۳. A.M. Firdaus, Y. Zaika, A. Munawir, Jurnal Rekayasa Sipil 14, 3 (2020) 14. Y. Zaika, H. Asyifa, M.A. Rofik, M. D. Sanjaya, International Journal of Geomate, 25, Issue 109. 237-245 (2023) 15. M. Carter, S.P. Bentley. Soil Properties and Their Correlations, Second edition. (Wiley, 2016) 16. P.R. Lewis, Forensic Polymer Engineering: Why Polymer Product Fail in Service (Woodhead Publishing, 2016) 17. A.A. Hilal, High-Performance Concrete Technology and Applications (InTech, 2016) 18. Directorate General of Highways (In Indonesian), The General Specifications for Road and Bridge Construction Work (The Ministry of Public Works and Housing, Indonesia, 2016) 19. Department of Public Works (In Indonesian), Design Guidelines for Stabilization Soil with Material Powder Binder on Road Construction (The Ministry of Public Works and Housing, Indonesia, 2007) 20. R.G. Robinson and M.M. Allam, 46, No. 5, 596-600, (1998) 21. A.L. Donald, D. Kalumba, in Proceedings of the 20th WasteConn Conference, 6-10 October 2014, Somerset West, Cape Town (2014)

لینک چکیده مطلب بالا به فارسی روان :بتن ژئو بید (Lightweight-GB) چیست و چه مزایایی برای بهسازی خاکهای نرم دارد؟

۸

Deformation moves from the top and spreads to the middle and the bottom. A high degree of deformation and distortion around the fracture zone will occur. Tearing of material accompanied by appreciable plastic deformation and exhibit necking.

The ductile fracture of GB30 and GB40 represents an overloaded part that breaks with invisible distortion and no plastic deformation. The crack will begin at a point of maximum stress and then grow across the section. The failure planes of samples with different portions of GB were identified through the same plane, namely the plane between GB and cement paste.

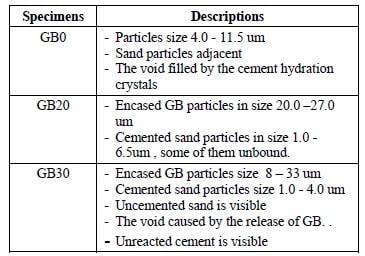

۳.۶ Microstructure of GB composite material

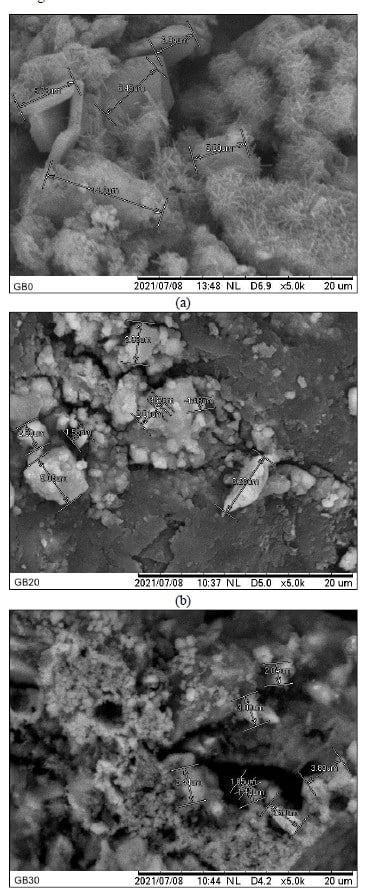

A Scanning Electron Microscope (SEM) is an instrument that produces images of a sample by scanning the surface. It makes various signals that contain information about the surface topography and composition of the specimen ( Table 7). GB composite is a heterogeneous material microstructure that leads to enhanced mechanical strength.

Figure 11 (a) is the SEM result of GB0 material consisting of cement paste and aggregate. The cement paste comprises unreacted cement, amorphous hydration products, and pores [17]. The sand aggregate has reacted with cement paste of various sizes. Unreacted cement looks like fine lines due to aggregate, cement, and water composition in unbalanced conditions. The presence of GB in the composite mixture causes some sand aggregates to unbind the cement paste, as shown in Figure 11 (b) and (c). There is cement paste, and GB forms large aggregates. Some released GB performs holes in composite material. Particle bonding also becomes more ductile with the increasing number of GBs

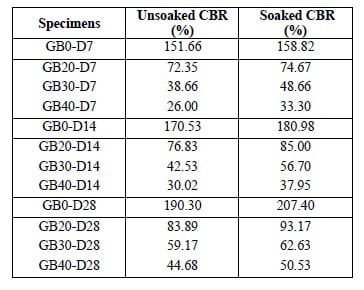

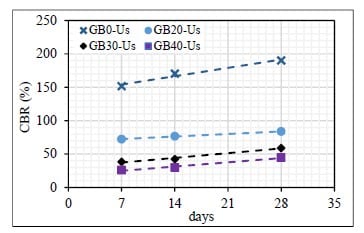

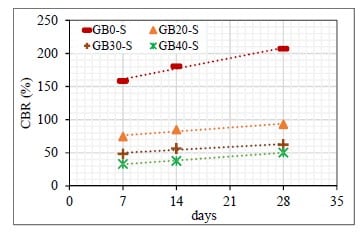

۳.۷ Califonia Bearing Ratio (CBR) composite material

Compared to GB0, the specimens with geo-beads (GB20, GB30, and GB40) have low CBR values (Table 8). This condition indicates that adding geo-beads can reduce soil strength. However, the curing time influences the strength significantly as shown in Figure 12 and 13. In this study, the soaked CBR is greater than the unsoaked CBR because the unreacted cement underwent a hydration process due to the availability of water. The absorptive nature of GB causes water shortage during initial mixing. It is necessary to consider the amount of required water for the hydration process by considering the absorbency of GB.

The requirement of CBR value depends on the layer where the fill material is used. The fill material must have at least 10% CBR for a capping layer on stabilized soft soil, 35% CBR for sub-base layers, and 90% CBR for the base layer [18, 19]. GB30 mixtures meet the criteria as backfill in the sub base layer, while GB20 qualifies as the base layer with respect to the amount of water required for complete cementation.

۳.۸ Settlement

The majority of soft soil settlements occur caused by primary consolidation. The total settlements of the embankment using conventional material without GB (sand soil), when the degree of consolidation is 90%, is 1.896 m.

Table 9 shows that at a composite 40% GB content, the settlement of the soft soil layer is smaller than that of sand fill, with a deviation of about 15.7 cm. Based on Terzaghi’s one-dimensional consolidation theory, the required consolidation time is expressed in the following equation:

۷

بدون دیدگاه